Sheet metal processing

- Categories:Solution

- Author:

- Origin:

- Time of issue:2021-10-28

- Views:0

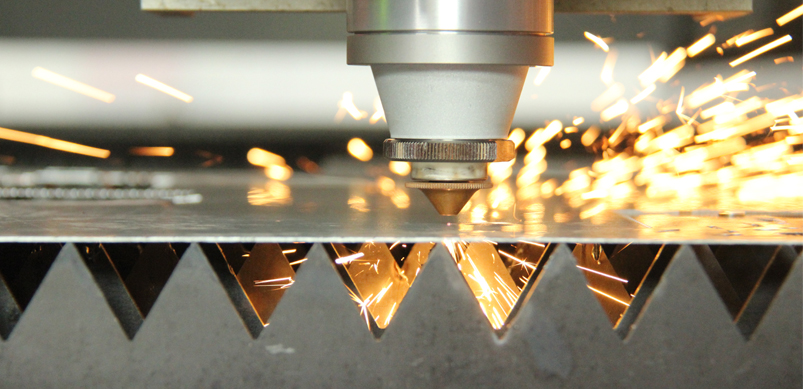

(Summary description)China has gradually become an international processing and manufacturing center. The demand for metal processing continues to increase, and the complexity of the process is relatively high. Even some parts have dozens of processes, and higher requirements are placed on sheet metal processing in terms of accuracy. Traditional sheet metal processing includes cutting, blanking and bending processes, among which the blanking process requires a lot of molds and wastes a lot of time and capital costs. Laser cutting is an efficient and high-quality flexible processing technology. Laser sheet metal processing does not require molds. Compared with traditional processing methods, laser cutting is simpler, more flexible, and has lower operating and maintenance costs. Huagong Laser has innovated and upgraded the laser cutting technology accumulated over the years, and launched a variety of advanced laser cutting equipment to provide efficient and professional laser sheet metal processing solutions for the sheet metal processing industry, and ultimately maximize the value of customers.

Sheet metal processing

(Summary description)China has gradually become an international processing and manufacturing center. The demand for metal processing continues to increase, and the complexity of the process is relatively high. Even some parts have dozens of processes, and higher requirements are placed on sheet metal processing in terms of accuracy. Traditional sheet metal processing includes cutting, blanking and bending processes, among which the blanking process requires a lot of molds and wastes a lot of time and capital costs. Laser cutting is an efficient and high-quality flexible processing technology. Laser sheet metal processing does not require molds. Compared with traditional processing methods, laser cutting is simpler, more flexible, and has lower operating and maintenance costs. Huagong Laser has innovated and upgraded the laser cutting technology accumulated over the years, and launched a variety of advanced laser cutting equipment to provide efficient and professional laser sheet metal processing solutions for the sheet metal processing industry, and ultimately maximize the value of customers.

- Categories:Solution

- Author:

- Origin:

- Time of issue:2021-10-28

- Views:0

China has gradually become an international processing and manufacturing center. The demand for metal processing continues to increase, and the complexity of the process is relatively high. Even some parts have dozens of processes, and higher requirements are placed on sheet metal processing in terms of accuracy. Traditional sheet metal processing includes cutting, blanking and bending processes, among which the blanking process requires a lot of molds and wastes a lot of time and capital costs. Laser cutting is an efficient and high-quality flexible processing technology. Laser sheet metal processing does not require molds. Compared with traditional processing methods, laser cutting is simpler, more flexible, and has lower operating and maintenance costs. Huagong Laser has innovated and upgraded the laser cutting technology accumulated over the years, and launched a variety of advanced laser cutting equipment to provide efficient and professional laser sheet metal processing solutions for the sheet metal processing industry, and ultimately maximize the value of customers.

Advantages of the new sheet metal cutting process

Laser cutting has a high degree of flexibility, fast cutting speed, high production efficiency, and short product production cycle. No matter it is simple or complex parts, you can use laser to achieve rapid prototyping cutting;

Narrow cutting seam, good cutting quality, high degree of automation, easy operation, low labor intensity, and no pollution;

Can realize cutting automatic layout, nesting, improve the material utilization rate, no tool wear, good material adaptability;

The production cost is low, and the economic benefit is good.

Most of the sheet metal processing is for large and medium-sized enterprises. The users have different products, high requirements, and urgent goods. Therefore, it is recommended to use high-power, large-format laser cutting machines. The high power improves the cutting ability while also improving the cutting efficiency; the format is large, the material utilization rate is high, and the cutting needs of different formats can be met at the same time.

Scan the QR code to read on your phone

Food Medical Industry

CONTACT US

Copyright © 2021 NAN JOINT PHOTONICS S&T CO.,LTD 苏ICP备2022002736号 By Word 300.cn